If you’re interested in procuring a commercial-ready kraft lignin plant, you have three options. Valmet, NORAM, Andritz, and a newcomer, SLRP.

Engineering & Processes

-

Valmet Lignoboost

LignoBoost works in conjunction with evaporation. The two-step process results in a very pure lignin with low ash content.

-

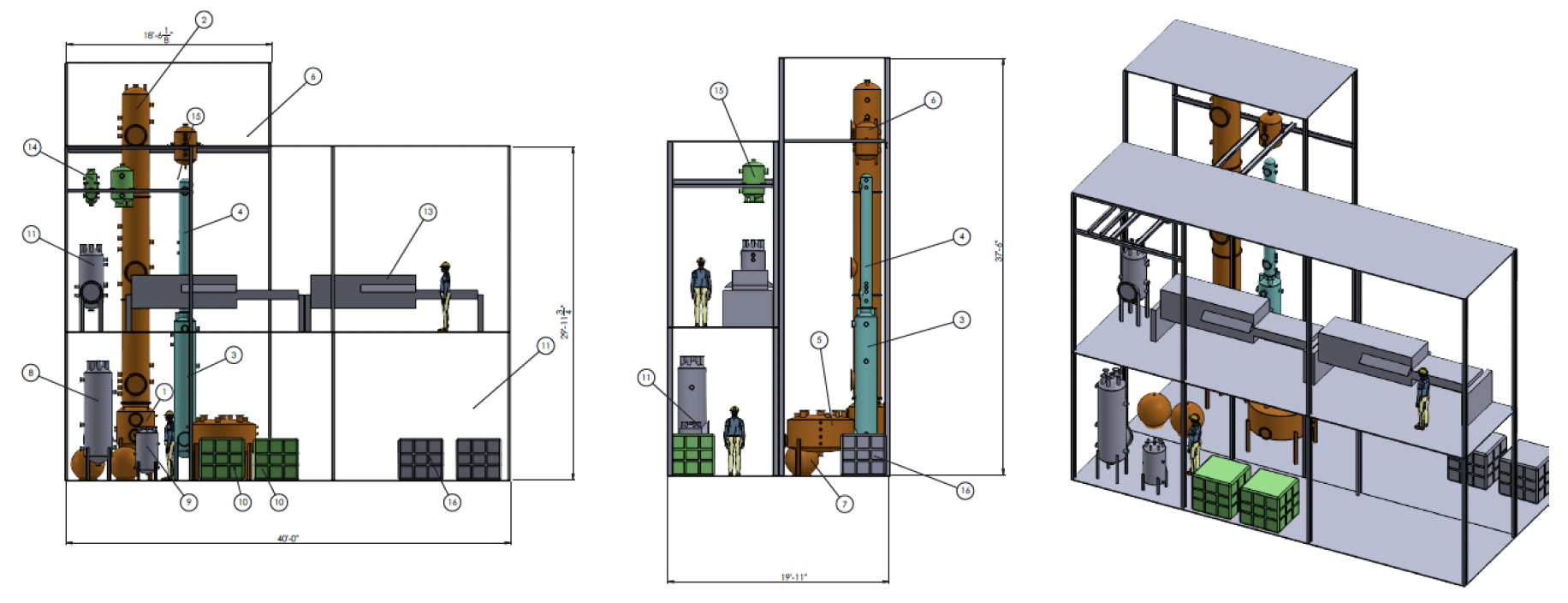

SLRP by Liquid Lignin Company

SLRP™ - an acronym for “Sequential Liquid-Lignin Recovery and Purification” – was developed using SBIR funding from the US Department of Energy. SLRPis continuous, is energy-efficient, requires low CAPEX and OPEX, and completely contains the off-gases in pressurized, air-free lines. The H2S is absorbed quantitatively and quickly in dilute NaOH solution so there is no exposure to operators. The single air vent stream is extremely small and contains low levels of innocuous organics. Because of its internal recycle streams, SLRP uses low levels of CO2 and H2SO4. SLRP’s porous lignin particles are easy to wash. Washing is done at elevated temperature (80°C) in-situ in the filter with pure water so low inorganic ash content is achieved in the lignin product with low excess water returned to the host mill. SLRP is protected by patents, the most recent being US Patent No. 11,866,456 which has been filed in Canada, the EU, Brazil, Chile, Indonesia and China.