SLRP by Liquid Lignin Company

Summary

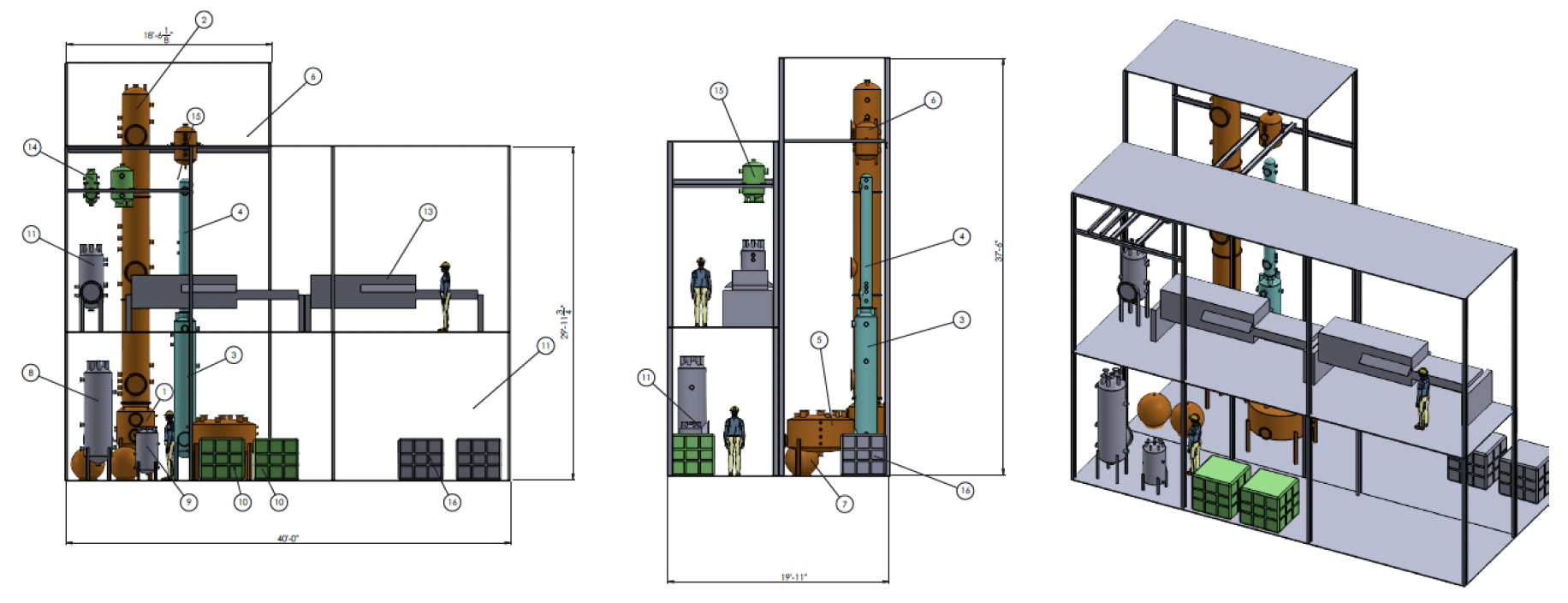

Using vessel sizes determined by Liquid Lignin Company, EnviroSep generated a 3D diagram of the demonstration SLRP capable of making ten (10) metric ton per day (Te/d).

Figure 1. 3D Diagram of Demo-SLRP

The skid size is 20-feet wide, 40-feet deep and 40-feet high.

Discussion

Vessels: All of the vessels are included:

Black Liquor Sand Filters (2)

Carbonation Column

Carbonation Column Knock-Out

Carbonation Settler

Vent-Gas Absorber

Vent-Gas Stripper

Carbonated (lignin-depleted) Black Liquor Neutralization

Acidification Reactor

Acidification Knock-Out

Lignin Slurry

Lignin Filter (2)

Acid Brine Recycle

Acid Brine Neutralization

Concentrated Sulfuric Acid Totes (2)

Concentrated Sodium Hydroxide Totes (2)

Not included in the 3D are:

Pre-Carbonation Column (very small);

Sulfuric Acid Mixing Tee with Recycled Brine (very small);

18 process pumps;

Piping and control valves;

Sensors, including nine (9) pH and three (3) viscosity measurements;

H2S monitor and alarm;

Master control system;

Collection bins under each filter and lignin supersacks;

CO2 dewar or tank- wagon;

Air compressor dedicated to Lignin Filter; and

Forklift for removing lignin supersacks.

Acid Side ↔ Base Side: The skid is in two equal halves separated by a short (≈ one-foot high) dike so that inevitable spills are separated. A sunken sump will be incorporated into each half with the concrete floor graded slightly to direct liquids to their respective sumps.

The base-side vessels are: Carbonation Column/Settler; Carbonation Column Knock-Out; Vent-Gas Absorber/Scrubber; Acid Brine Neutralization, Carbonated Black Liquor Neutralization; Sand Filters; and Concentrated NaOH totes. The acid-side vessels are: Acidification Reactor; Acidification Reactor Knock-Out; Lignin Slurry, Lignin Filters (2); Acid Brine Recycle; and Concentrated H2SO4 totes.

Filters: Two Watermark filter will operate in parallel. One will be accumulating lignin while the other goes through wash cycle which includes:

Wash with pure water at 80 °C;

Squeeze cakes with pressurized bladders within each cell to remove water;

Blow filter with air to remove residual water;

Separate plates to allow lignin cakes to dump; and

Reclosing plates to begin filtering lignin.